Why Granite Processing is a Challenge and How to Pick the Perfect Crusher for It

Granite processing is no casual endeavor; it’s a battle of brains versus brawn. The granite industry might not be the first to pop up when thinking about challenges in manufacturing, but don’t be fooled—it’s a world of unyielding hardness and complexity. For those seeking to crack this robust stone, a strategic approach to selecting the perfect granite crusher machine is paramount.

The Immutable Challenges of Granite Processing

Unyielding Hardness and Density

Granite might as well be the poster child for stubbornness in the stone world. With a density that often exceeds 2.7 grams per cubic centimeter, it is, without question, a formidable opponent. Crushing it requires not just power, but the ability to withstand extreme force. Unlike softer aggregates, granite doesn't crumble easily. This means higher wear and tear on the equipment, frequent maintenance, and a hefty energy bill. But, of course, if it were easy, everyone would be doing it.

The Unseen Complexity of Granite Composition

Granite isn’t just about its weight and toughness; its very composition makes it a challenge. It’s composed of a mix of minerals—quartz, feldspar, and mica—which varies widely from one deposit to another. These variations complicate the grinding and crushing process. Some granites are full of hidden cracks and inclusions that resist traditional processing methods. This makes it imperative to understand exactly what you're dealing with before selecting the right equipment.

The Hunt for the Right Crusher

Understanding Crusher Types: What’s Best for Granite?

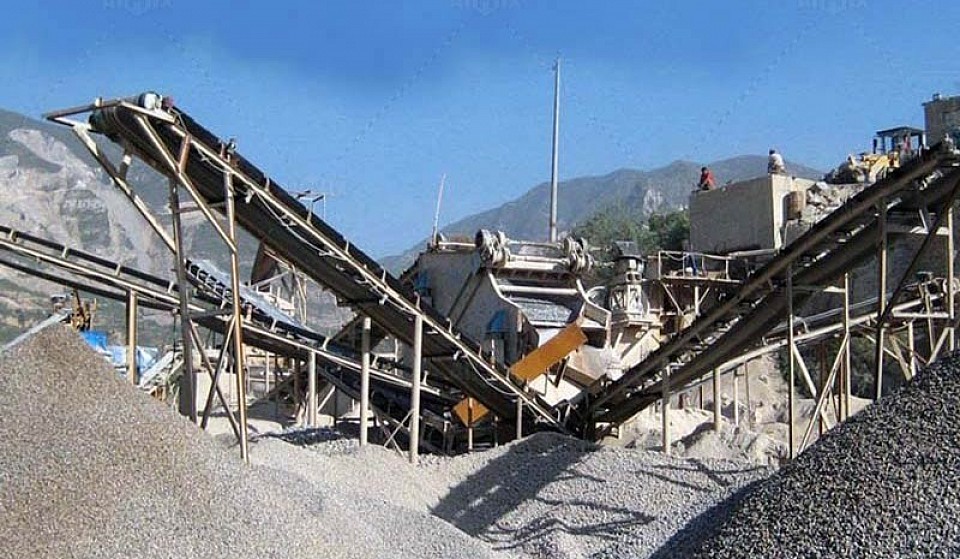

Not all crushers are created equal. The best one for granite might not be the best for limestone, and certainly not for coal. Jaw crushers, cone crushers, and impact crushers each serve distinct purposes, but their suitability for granite varies. Jaw crushers work well for primary crushing but might struggle with the more delicate parts of granite. Meanwhile, cone crushers, with their precise, finely-tuned crushing action, are often the go-to choice for granite. Impact crushers, though fantastic for softer materials, tend to leave a dent in granite rather than break it apart.

Factors to Consider in Crusher Selection

Choosing a crusher for granite requires more than just selecting a machine that "looks cool." Efficiency, maintenance needs, and operational costs are key. For instance, the crushing capacity of the crusher should match the production demands. But the real question is: how well does it stand up to the job over time? A crusher’s wear life, especially its liners and hammers, is critical when processing granite. Equally important is its energy consumption; after all, smashing granite requires considerable power.

Overcoming the Granite Challenge: Choosing Wisely

The Role of Technology in Crusher Performance

Advances in technology have revolutionized the granite crushing industry. Modern crushers are far more intelligent than their predecessors. Sensors, automated control systems, and data analytics allow crushers to adapt to the ever-changing demands of granite processing. With real-time performance monitoring, you can predict potential failures, adjust operations accordingly, and optimize the crushing process for maximum efficiency. The right technology ensures not only effectiveness but also longevity, sparing you from frequent downtime.

Cost vs. Long-Term Efficiency

At first glance, a high-capacity, durable crusher might appear prohibitively expensive. However, when compared to lower-end models that might require constant repairs and replacements, investing in a quality aggregate crusher for sale is often the more cost-effective route. The key lies in balancing initial investment with long-term operational costs. A reliable, high-performance crusher means reduced downtime, lower maintenance expenses, and ultimately, a higher return on investment.

Granite processing isn't for the faint-hearted. It requires a strategic approach, from understanding the stone's unyielding nature to picking the right crusher for the task. By recognizing the challenges and making informed choices, businesses can turn what seems like a formidable obstacle into a profitable venture.